Product successfully added to your shopping cart

There are 0 items in your cart. There is 1 item in your cart.

Presented materials prove that shaped sealing bars are better than standard sealing bars.

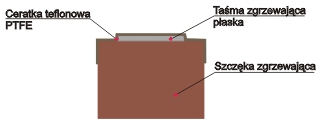

The diagram shows the work of sealing jaws with the use of standard sealing bar. The tape is currently used in most sealing and packaging devices.

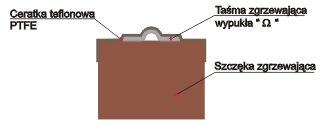

The diagram presents the jaws which is working with the shaped sealing bar Omega of a convex shape. The use of that model significantly improves the quality of the weld. The foil is sealed on the full width. The shaped sealing bar adjusts the silicone placed on pressing jaw disposing of air bubbles, liquids and any pollution. Side brackets of the bar prevent it from moving during the process of sealing.

As a result the weld is much more durable, which is very important in case of packaging dusty products, liquid substances, frozen food. This model can be used as perfect replacement for standard sealing bars. The resistance of the bar Omega 4/0,3 is the same as the resistance of standard sealing bar 4x0,3 mm.

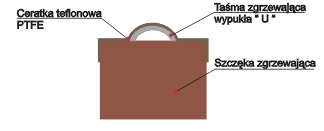

The diagram depicts the jaw equipped with shaped sealing bars U convex . This bar characterizes by much more endurance and reliability of weld. Its shape prevents fromgas bubbles as well as dirt around the sealed area. Presented bar is recommended for sealing the foil intended for storage of dusty products, liquids and frozen food as well as other, less demanding products.

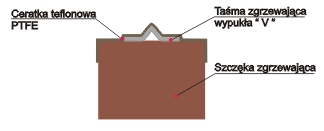

The diagram presents jaw with is equipped with shaped sealing bars V convex. This Model is designed not only to make high quality weld but also to cut off the excess of foil in the package. In addition the V shape causes that closing the packages which contain wet, dusty and dirty products is possible. That demands special weld of high endurance and reliability. Side brackets of the bar prevent it from moving and guarantee the stability of the position.

Categories

- PTFE coated fiberglass fabric

-

PTFE coated fiberglass tapes

- Adhesive PTFE coated fiberglass tapes

- PTFE coated fiberglass tapes - without adhesive

- Two-edge adhesive PTFE tapes

- Adhesive PTFE coated fiberglass tapes

- Pure PTFE Adhesive tapes

- Nitto Tapes

- PTFE belts

- Silicone fabric

- Sealing bars

- Sealing wires

- Busch oils and filters

- Silicone sheeting

- Silicone rubber

- PTFE spray

- Technical sprays

- Nitto tapes