Product successfully added to your shopping cart

There are 0 items in your cart. There is 1 item in your cart.

View larger

View larger

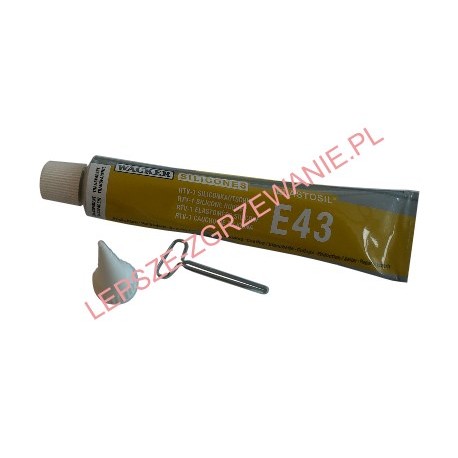

Silicone Rubber ELASTOSIL E43 -90 ml

ELASTOSIL

New product

ELASTOSIL® E43 N is a non-slump to self-levelling silicone rubber formulation, which cures at room temperature under the influence of atmospheric moisture to yield a silicone elastomer with very good mechanical properties.

More info

Product description

ELASTOSIL® E43 N is a non-slump to self-levelling silicone rubber formulation, which cures at room temperature under the influence of atmospheric moisture to yield a silicone elastomer with very good mechanical properties.

Special features

- acetic acid-curing system

- non-slump to self-levelling

- fast curing

- excellent primerless adhesion to many substrates

Processed vulcanizates ELASTOSIL® E43 N are suitable for use under the Recommendation "XV. Silicones" of the BfR and 21 CFR § 175.300 "Resinous and polymeric coatings" and FDA 21 CFR §177.2600 "Rubber articles intended for repeated use" under observance of any given limitations on extractable and volatile substances. Residual solvents have to be completely removed from the food contact article.

Application

- multipurpose glue, in particular for food related applications

Processing

ELASTOSIL® E43 N cures at room temperature under the influence of atmospheric moisture:

Skin-forming time, 23 °C, 50 % RH 5 - 10 min

Curing time, 23 °C, 50 % RH 12 h/mm

The fully cured material typically shows good primerless adhesion to many substrates. We recommend to run preliminary tests to optimize conditions for the particular application.

Elastosl E-43 is resistant to oils and aging resistant. The glue retains its properties for 12 months from date of manufacturing when stored in original unopened packaging. After opening the tube the entire contents should be used as quickly as possible. Opened tube should be kept in a foil bag firmly tightened in the temperature of around 5 °C. Using Elastosil E-43 glue guarantee permanent connection of silicone items as well as silicone and metal.

The technology of preparing the surface and the glue:

1. Degrease the glueing surface thoroughly (extraction petrol, toluene, acetone).

2. Apply thin layer of glue.

3. Clench the items gently for the time of glueing.

4. The durability of joint is achieved after 24 hours (in case of thick joints – after about 48 hours)

The process of glueing should take place in the temperature no lower than +20 °C, in the highest possible air humidity.

Storage

The 'Best use before end' date of each batch is shown on the product label.

Storage beyond the date specified on the label does not necessarily mean that the product is no longer usable. In this case however, the properties required for the intended use must be checked for quality assurance reasons.

Safety notes

During vulcanization of ELASTOSIL® E43 N, a total of about 3.5 % by weight of acetic acid is split off. These vapours should not be inhaled for long periods or in high concentration. Work areas should therefore be well ventilated. Contact of unvulcanized silicone rubber with eyes and mucous membranes must be avoided as this would cause irritation. However if it does happen, rinse the affected area thoroughly with water.

Comprehensive instructions are given in the corresponding Material Safety Data Sheets. They are available on request from WACKER subsidiaries or may be printed via WACKER web site http://www.wacker.com.

Categories

- PTFE coated fiberglass fabric

-

PTFE coated fiberglass tapes

- Adhesive PTFE coated fiberglass tapes

- PTFE coated fiberglass tapes - without adhesive

- Two-edge adhesive PTFE tapes

- Adhesive PTFE coated fiberglass tapes

- Pure PTFE Adhesive tapes

- Nitto Tapes

- PTFE belts

- Silicone fabric

- Sealing bars

- Sealing wires

- Busch oils and filters

- Silicone sheeting

- Silicone rubber

- PTFE spray

- Technical sprays

- Nitto tapes